- info@ems-ltd.com

- 0118 9817391

Home > PR > Brushed vs Brushless motors

Brushed vs Brushless motors

27/11/2021

22nd November 2021

Filed under:

Ems, Faulhaber, Brushed, Brushless

Mathematician Alfred North Whitehead once said: “It takes an extraordinary intelligence to contemplate the obvious”. While the crucial distinction between brushed and brushless motors, the presence or absence of brushes, is evident, the implications of their differences are much more complex. Here Dave Walsha, sales manager at brushed and brushless motors supplier EMS, shares his insight through a detailed comparison of the two motor types.

The presence or absence of brushes in a motor determines its type of commutation. To generate motion in the two types of motors, there must be a switching sequence of drive voltage into the motor phase windings to energise them appropriately. This ensures continuous motor rotation, and is known as commutation.

Brushing up on basics

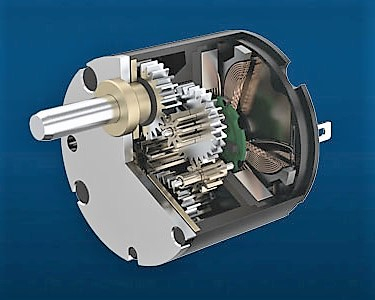

Brushed motors use brushes in a mechanical type of commutation. The brushes push on different segments of the motor’s commutator, and as the rotor turns, the portion that is energised switches. In a brushed motor, the magnets stay still as the stator and the rotor spins.

In brushless motors, commutation is carried out electronically, where a control unit is required to switch power in the motor windings to create torque. In contrast to brushed motors, the magnet inside a brushless motor spins and instead the windings stay still as the stator.

Advantages and disadvantages

Because of their different methods of commutation, brushed and brushless motors have varying benefits and drawbacks. For instance, as brushed motors rely on internal mechanical commutation, they are overall easier to power up. With no need for an electrical control unit, they can work in a simple electronic system.

However, the brushes inside will wear down from constant contact with the commutator, giving brushed motors a shorter lifecycle than brushless. For instance, graphite, a common brush material, will often only last around 3,000 hours in a motor before wearing down. The brushes in motors running at lower speeds can also suffer from build-up of deposits if the speed isn’t high enough to propel the deposits off.

In contrast, brushless motors have no wear component except for their bearings, which typically have a long life, and thus can operate for tens of thousands of hours. In addition, as commutator wear isn’t a concern with brushless motors, they can safely be operated at tens of thousands of revolutions per minute (rpm), as opposed to the 5,000 to 10,000 rpm more typically seen for brushed motors.

The speed of a brushless motor can be controlled very finely across a wide range thanks to its electronic commutation. However, this does mean the motor requires some sort of feedback to operate, such as hall sensors, which detect the magnetic field of the rotor. With the need for a control unit and method of feedback, brushless motors are overall a more complex system.

Evaluating applications

The long life of brushless motors makes them the best choice for applications where the piece of equipment must operate for long periods of time. This includes devices such as dental tools, cordless vacuum cleaners, pumps, drones and robots.

In contrast, brushed motors are a simple solution for projects that do not require a long life or constant speed control. Some examples include car seat adjustment, toys and power tools.

Determining whether to select a brushed or brushless motor depends on the application requirements, which is why it’s important to work with an expert supplier who can support the decision. EMS offers a wide range of brushed and brushless motors to choose from, so that design engineers can find the optimal solution for their unique project.

For instance, EMS supplies FAULHABER ironless brushed motors, which offer a higher performance than typical brushed motors. Their optimised design with ironless core rotor technology provides them with an unrivalled power to weight ratio. The range offers the simplicity of a brushed motor, but many of the performance characteristics typically associated with a brushless motor.

Design engineers must delve beyond the obvious distinction between brushed and brushless motors to uncover each type’s talents. By selecting a motor with optimised features, such as an ironless core, design engineers can achieve the best of both worlds.

Not sure which type is best for your needs? Discuss your application with one of our experts today and discover the best drive system for you.

- Categories / Tags

- 1024...SR

- AEMT

- AESL

- Acceleration

- Agriculture

- Agritech

- Autoclave

- BHS

- BHT

- BHx

- BLDC

- BP4

- BRC Series

- BX4

- BXT

- BeBionic

- Bearings

- Bespoke

- Brushed

- Brushed DC Motors

- Brushless

- Brushless DC Motors

- Brushless Dc Motors

- Brushless Motor

- Buhler

- Building Automation

- COVID

- CXR

- Catalogue

- Company Update

- Controller

- Coreless

- Coventry

- Custom

- Custom Design

- DC Motor

- DC Motor Supplier

- DMN

- Dc Motor

- Design

- Dimatech

- Drones

- EDS

- EMS

- EMS News

- EV

- Encoder

- Ewellix

- Exoskeleton

- Expo

- FAULHABER

- Factory

- Faulhaber

- Flat

- GPT

- Galil

- Gearhead

- IEF3

- IMC

- Industry 4.0. Blog

- Inspection

- KAG

- LL06

- LM

- LVC

- Laboratory Automation

- Linear

- Linear Actuator

- Logistics

- M50

- M80

- MC3

- Maintenance

- Manufacturing

- Mechatronics

- MedTech

- Medical

- Medical Devices

- Medical Imaging

- Medtech

- Merkel

- Motion Control

- Motor

- Neurosurgery

- New

- Nidec

- Nidec Servo

- Optical

- Pain Relief

- Piezo

- Piezomotor

- Pipeline

- Planetary

- Planetary Gearheads

- Point Of Care

- Precision

- Precistep

- Process

- Production

- Quickshaft

- Robot

- Robotics

- Robots

- SKF

- SR Series

- Samples

- Small DC Motor

- Software

- Space

- Sponsorship

- Stepper

- Stepper Motor

- Stepper Motors

- TMS

- Testing

- Trade Show

- 1016

- 1660

- 1935

- 2017

- 2018

- 2020

- 2021