- info@ems-ltd.com

- 0118 9817391

Home > Custom design > Metrology

Metrology and quality for custom drive systems

At EMS, we know that precision in metrology is essential for delivering quality across complex industries. That’s why our comprehensive metrology process for custom drive designs supports quality assurance throughout every stage of our manufacturing process, ensuring that components and assemblies meet exact specifications and perform reliably in your application.

From the initial inspection of materials to rigorous end-of-line testing, EMS’s expertise and cutting-edge technology make us the trusted choice for high precision measurement solutions.

Our manufacturing inspection process

To ensure that every component meets the highest standards, we implement detailed inspection and testing protocols at every step of the manufacturing process:

Incoming material inspection: Each material and component is inspected before acceptance into stock, verifying that it meets quality and performance standards.

First-off inspection: During the manufacturing setup, we conduct first-off inspections to ensure compliance before full production begins.

In-process inspection: Our experienced inspectors perform roving inspections throughout batch manufacturing to monitor and maintain quality.

Sample-based final component inspection: For each batch, we conduct thorough inspections against a predefined sample plan, guaranteeing consistency and precision.

Comprehensive assembly testing: Every assembled component undergoes a final inspection and test to ensure it meets both EMS’s high standards and specific customer requirements.

End-of-Line (EOL) testing: Our EOL testing is tailored to meet both EMS and customer-driven specifications, providing the confidence that all products will perform reliably in their intended applications.

Metrology and inspection equipment

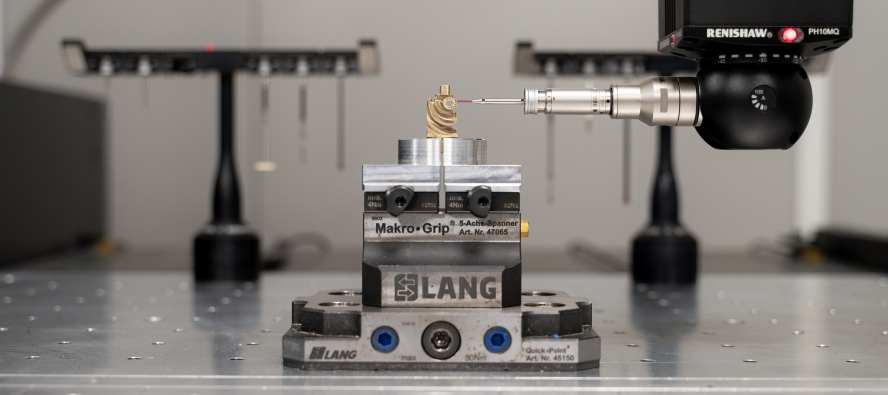

To maintain the highest standards of precision, EMS has invested in leading-edge metrology equipment, including the Mitutoyo 1076 CNCCMM, Sylva Scan S25T, Mitutoyo Quick Vision Active, Mitutoyo QM333, and Trimos V4, as well as a variety of manual metrology tools.

As specialists in manufacturing and inspecting gears for use in high-performance gearboxes, EMS uses dedicated gear measurement equipment. With advanced tools like the Rolling Gear Tester, Mitutoyo Gearpak, gear micrometers and custom fixtures, we ensure that every gear we produce and inspect meets precise tolerances required for critical applications.

Bespoke precision measurement solutions

EMS also designs and manufactures custom test and measurement equipment tailored to specific client needs. From line fixtures to inspection devices and end-of-line test equipment, we deliver solutions engineered for your unique requirements, ensuring the product’s performance aligns with both the application and customer expectations.

With a commitment to precision in metrology and inspection, EMS helps to ensure that your products meet industry and customer standards with accuracy and reliability. To learn more about the metrology and inspection process behind custom drive designs, contact the team today.